Comparing Asphalt Installations With and Without ACE XP Polymer Fiber

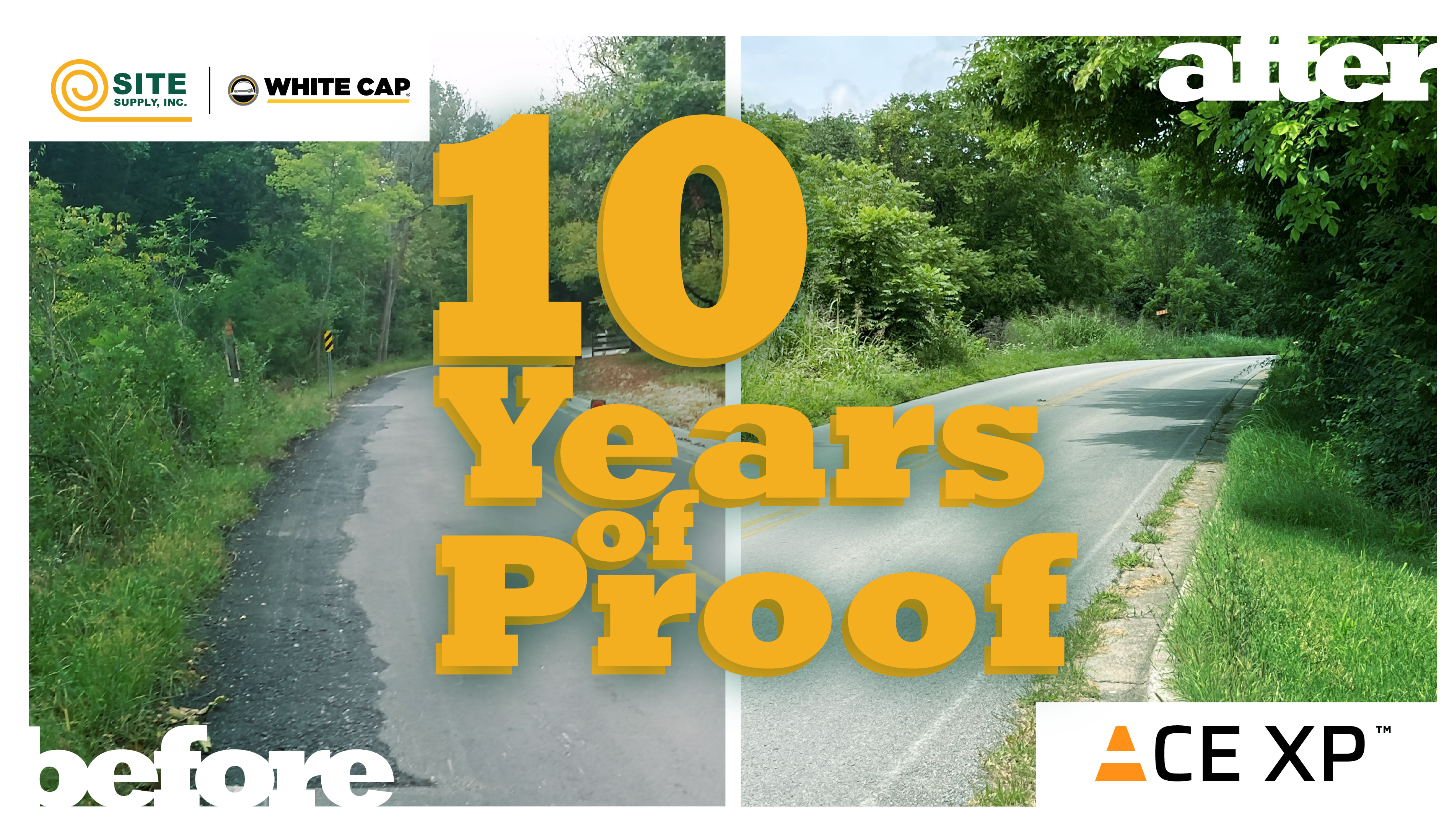

In 2015, two Love’s Travel Stops were constructed in close succession—one in Sadieville, KY, and another at a control location. Both sites experienced similar traffic volumes, with over 1,000 cars and semi-trailer trucks passing daily. Despite having slightly different subgrade conditions and pavement thicknesses, both projects were designed for a 20-year service life. However, the key difference was that the Sadieville location incorporated ACE XP Polymer Fiber, while the control site did not.

ACE XP Polymer Fiber

by Surface Tech

ACE XP Polymer Fiber, developed by Surface Tech, is a high-performance aramid fiber designed to reinforce asphalt pavements. The fiber, treated with a patented wax binder, disperses evenly into hot mix asphalt (HMA) and warm mix asphalt (WMA), providing enhanced durability without altering the mix design’s volumetric properties. This reinforcement improves the pavement’s resistance to rutting, cracking, and fatigue, extending its service life even in high-stress areas such as entrances and turning lanes.

Benefits of ACE XP Polymer Fiber

- Increased Durability: The fiber-reinforced asphalt resisted rutting and cracking, even in high-stress areas, improving the overall pavement lifespan.

- Cost-Effectiveness: The extended service life of the pavement reduces long-term maintenance and repair costs.

- Environmental Impact: ACE XP is a low-carbon, sustainable product, with certifications such as the EPD (Environmental Product Declaration)

Project Comparison

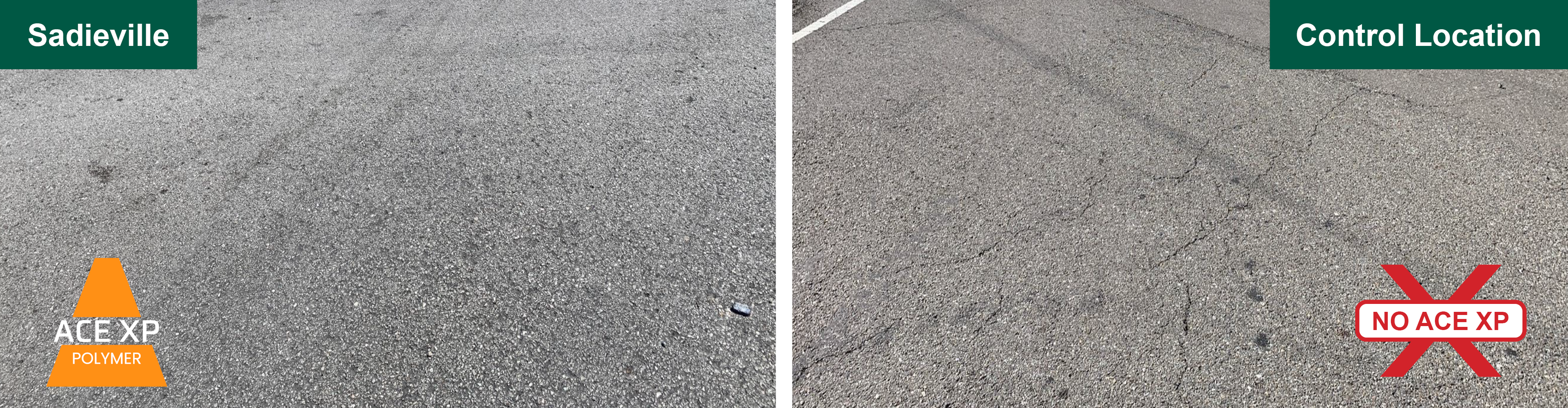

Sadieville (with ACE XP) vs. Control Location (without ACE XP)

Both projects were subjected to significant stress due to the high volume of heavy vehicles. After four years, noticeable differences emerged between the two sites:

High-Stress Areas

- Sadieville: The turning lanes and entrances remained in excellent condition with no signs of cracking or rutting.

- Control Location: Fatigue cracking and rutting were already evident, necessitating patchwork repairs.

- Sadieville: Only minimal cracking at the cold joints was observed, while the overall pavement condition remained strong.

- Control Location: Widespread fatigue cracking had begun to develop, indicating reduced durability.

- Sadieville: Only minor deformation and cracking were observed at

these critical points. - Control Location: Significant deformation, revealing concrete edges, created water traps and potential trip hazards.

Conclusion

The comparison of these two Love’s Travel Stop projects highlights the significant advantages of incorporating ACE XP Polymer Fiber into asphalt mixes. The Sadieville site, reinforced with ACE XP, demonstrated superior durability, fewer repairs, and a longer service life compared to the control location. This case study underscores the value of using advanced reinforcement technologies like ACE XP in commercial applications to enhance pavement performance.